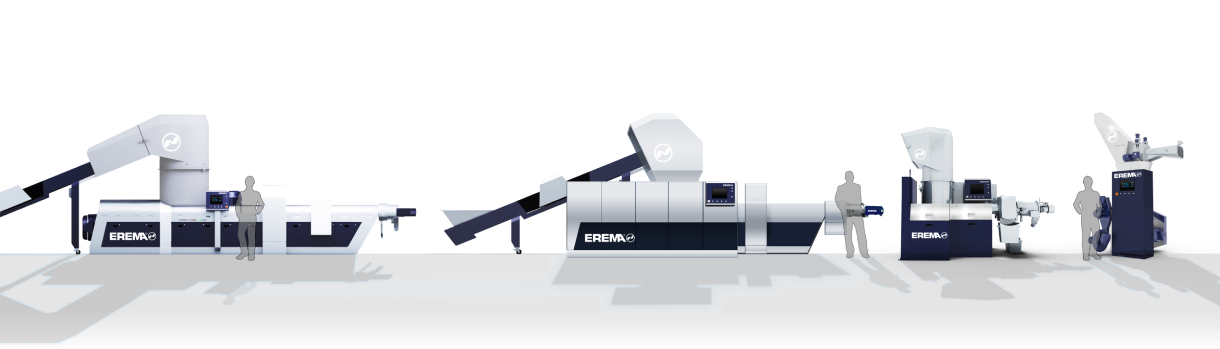

EREMA is the world market and innovation leader in the development and production of plastic recycling plants and components at the highest quality level. For thirty years the Upper Austrian company based in Ansfelden near Linz has served as the globally leading standard for various tasks relating to in-house recycling of production waste as well as for heavily contaminated post consumer waste. EREMA boasts more than 50 national representatives across the globe as well as company subsidiaries. Today more than 4,000 EREMA systems around the world produce over 14 million tons of plastic pellets each year.

INTAREMA

Revolutionary Technology with a new look

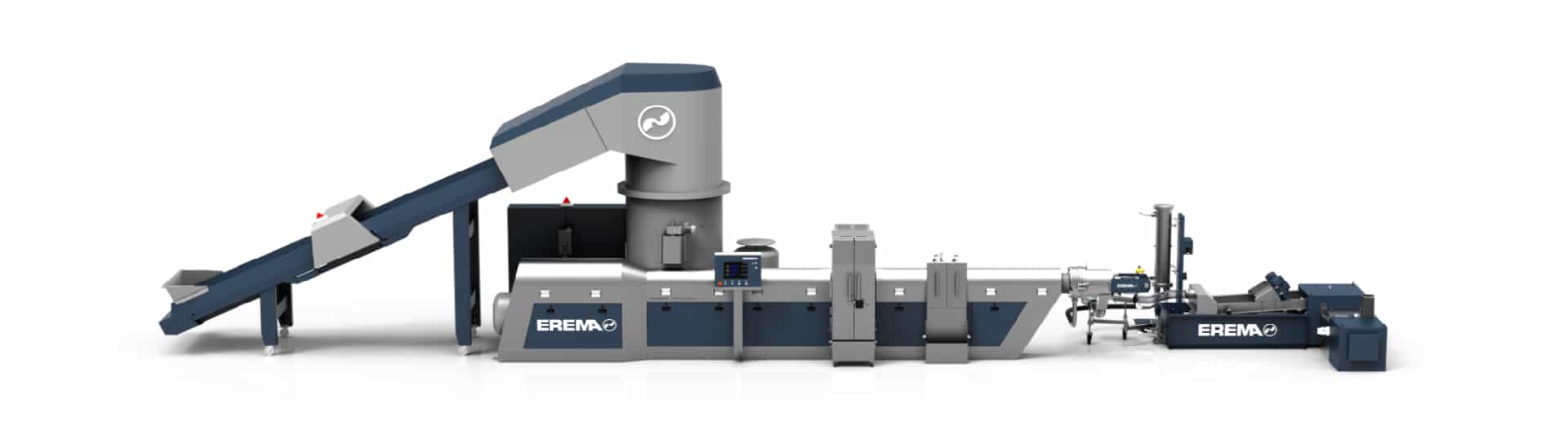

Thanks to EREMA, high-grade regranulates which comprise valuable secondary raw materials are derived from the plastic waste materials. The decisive factor is the stable and gentle recycling process. This is ensured by the revolutionary, patented Counter Current System and other groundbreaking technical innovations integrated into the new plastic recycling facility called INTAREMA®.

The results are the highest level of productivity, flexibility and operational reliability based on the easiest use and considerably reduced energy consumption.

These attributes and the further development of the technology are optimally conveyed at first glance by the dynamic design of the recycling plant implemented by Spirit Design.

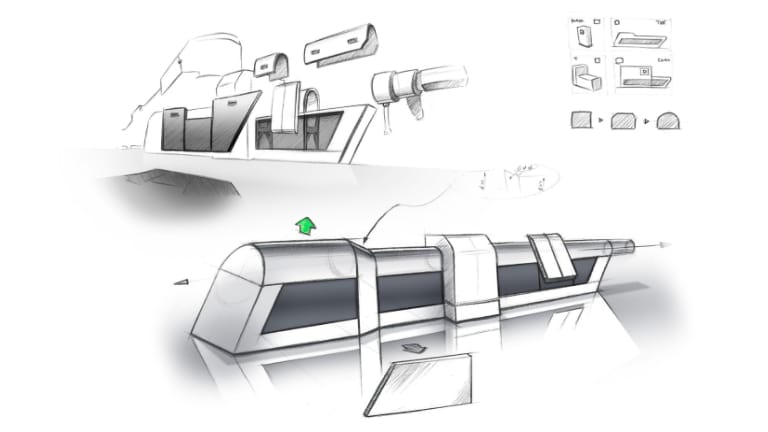

Functional and streamlined form

The puristic, linear outer design by Spirit Design perfectly highlights the innovative core technology and the new gear units driving INTAREMA®. Thanks to the changed plant setup, the maintenance-friendly nature of the facility is increased. Accordingly, high-maintenance parts are easily accessible.

With respect to the design, the focus was on simplicity and straightforwardness and not the design as an end in itself. The perfect engineering of the plant transports a very clear product message, and the innovative and high-performance technology is optimally reflected in the appearance of the facility. This makes a significant contribution to a positive purchasing decision, also with capital goods.

Emphasis was also placed in production costs in developing the design. The optimized housing is reflected in the slim design and minimized casing of forms made of real materials, in this case easy care, low maintenance sandblasted high grade steel. The formal concept takes the entire product portfolio of EREMA into account, and can thus be applied as a visual product language to other plants as well as adjacent assemblies to feed in and further process the waste materials.

User-friendly like a smart phone

The design attached particular importance to the control panel of INTAREMA®. As an important interface between man and machine, it ensures optimal usability. Thus the user interface offers an intuitive use which is similar to the smart phones in the consumer goods segment.

Just a very few, clearly understandable symbols ensure simple and language-independent use. The interface conveys the efficiency of the entire plant by providing information on all important machine parameters.

Visual Product Language (VPL)

Comprehensible quality

Visual Product Language (VPL) optically expresses a corporate strategy at the product level and reinforces its brand presence. It serves not only to differentiate products from other market players but also to enhance their recognizability.

We developed a comprehensive VPL for EREMA and compiled all the respective guidelines in a clearly structured manual with that will shape all further product developments and future plant generations.

Unmistakable appearance

We conceived an independent product language based on the positioning and characteristic brand values of EREMA. The branding as well as material and color concept we have defined lays the foundation of applying the signature design and its core elements to all types of plants. This process ensures consistency in design.

The EREMA design language visually expresses EREMA’s leadership in innovation. Its reduced, functional and clear-cut character conveys both ergonomics and servicing friendliness. The design particularly highlights the applied technology by focusing on the plant’s core. All forms and shapes follow the processing direction: its distinct and linear product language communicates functionality, efficiency and clarity.

Visualized innovation

Aside from structuring company logo, signet and typing on the recycling plants, our revised VPL for EREMA also includes a material, color and surface concept. Deliberate contrasts in colors and materials support the differentiation of components which not only meet but also visually underline both functional and ergonomic user requirements. They are substantial, durable, and stand for high value, precision, reliability and solid quality.